Process

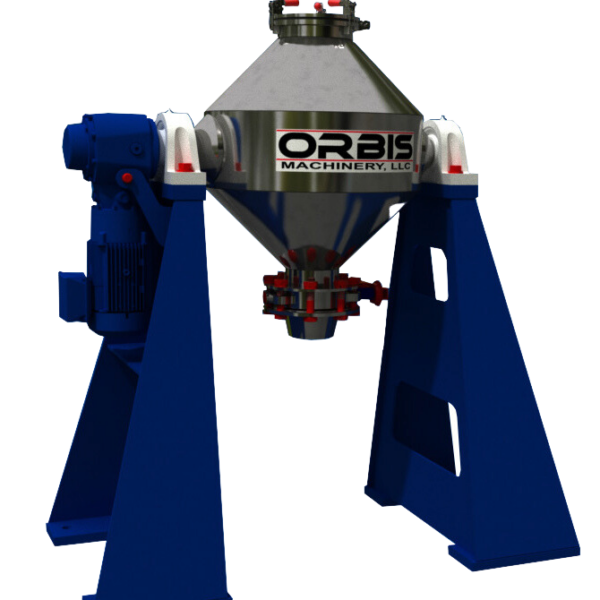

Tumble drying of materials is accomplished by heating the walls of a jacketed, slow rotating double cone shaped vessel while applying vacuum. By applying vacuum, the boiling point of the liquid component(s) is lowered, while constant particle contact with the vessel walls provides uniform drying action. Revolving dryers rotate at low speeds (3 to 12 RPM, depending on the capacity of the dryer).

The heating jackets can be supplied for operation at 100° to 500° F. As a standard, all our hot oil or steam jackets include high temperature insulation covered by a watertight insulation shroud. Heating of the jacket is commonly accomplished using hot oil, but other heating sources such as steam or electric blankets, may also be used. Using oil as the heating medium, allows for faster cooling of the product after the material has been dried, for faster and safer unloading and handling.

Design

Two cones are welded to a cylindrical center section providing a gentle, low shear, tumble action of the product. Our cone tumble dryer design results in a high degree of particle mobility without the use of internal baffles (45° and 60° cones are available). Cone tumble dryers have been proven in a wide variety of industries, offering greater overall volume and high efficiency.

Options

Orbis offers a wide variety of options. Each machine is tailored to your specifications and applications. Our dryers handle a variety of material densities and are easily adaptable to meet standard material handling systems. Whichever your dryer requirements are, we have a solution to fit your process.

Standard Features

- Standard Designs for Material Densities up to 250 lbs. Cu. ft.

- 0.5 to 500 Cubic Foot Working Capacities

- 304 or 316 stainless steel or Carbon Steel construction

Design Options

- Operator/Control Panels

- Pneumatic Valve Operation and Interlocks

- Sampling

- Internal and external finishes ranging from Mill to Mirror

- Various vessel interior coatings

- Containment systems

- Indexing Systems

- Load Cells

- Metallurgy

- Hastelloy C276 or C22

- Inconel

- Clean In Place

- Drum Loading System to accommodate any Drum Size and weight

- Pneumatically Operated Drum Roller Tray Lift Assembly, Pre-Wired with Safety Interlocks

- Vibrators for Poor Flowing Materials

Click for product sheet & various models

Vendor Information

- Store Name: ORBIS MACHINERY, LLC

- Vendor: ORBIS MACHINERY, LLC

-

Address:

2001 S. Prairie Ave

Waukesha, WI WI 53189

United States (US) - No ratings found yet!

Product Location

2001 South Prairie Avenue, Waukesha, Wisconsin 53189, United StatesPaddle Blender / Ribbon Blender Orbis Machinery HMD

In stock

*Extended Return Policy Agreement between Party A (Buyer) and Party B (Supplier) on Grooft B2B Marketplace:*

This comprehensive Return Policy establishes the terms and conditions governing returns, refunds, and dispute resolution between Party A (Buyer) and Party B (Supplier) participating in transactions on the Grooft B2B Marketplace. Both parties mutually consent to the following guidelines:

1. Reporting Damaged or Defective Goods:

– Party A is obligated to promptly report any damages or defects in the received goods within 7 days of the goods being delivered.

– Clear photographic evidence must be provided by Party A to Party B to facilitate an expeditious resolution process.

2. Reporting Quality Issues:

– In instances where the goods received by Party A are of substandard quality, Party A is required to inform Party B within 7 working days from the date of receiving the goods.

– Comprehensive documentation and evidence supporting the claim of substandard quality must be provided to Party B.

3. Late Delivery Notification:

– Party A is required to report any instances of late delivery within 24 hours of receiving the goods.

– Late delivery claims should include pertinent details such as the shipment tracking information and the anticipated and actual delivery dates.

4. Overpayment by Mistake:

– Should Party A make an overpayment or duplicate payment by mistake, Party B agrees to promptly process a refund for the excess amount.

– Both parties commit to ensuring that financial transactions are accurately documented and discrepancies are addressed in a timely manner.

5. Order Cancellations:

– Party A retains the right to cancel an order within the agreed-upon cancellation period.

– Notice of order cancellations must be provided to Party B before the order is shipped or within the stipulated cancellation timeframe.

6. Partial Shipments and Quantity Discrepancies:

– In the event of partial shipments or discrepancies in the quantity of goods received, Party A must inform Party B within 7 days of receiving the partial shipment or noting the quantity discrepancy.

7. Service-related Matters:

– If the transaction involves services, Party A should report any dissatisfaction or issues with the services provided by Party B within 7 working days of the completion of the service.

8. Financial Agreements Settled Outside Grooft B2B:

– Acknowledging that financial agreements and payment settlements may occur outside the Grooft B2B Marketplace, both parties agree that the management of Grooft B2B is not responsible for dispute resolution in such cases.

– Disputes related to financial matters settled outside the platform will be resolved directly between Party A and Party B.

9. Applicable Law:

– Both parties recognize that the laws of the respective country of residence will govern their transactions and any disputes that may arise.

– The agreement to adhere to local laws fosters a fair and equitable resolution process.

10. Mutual Agreement on Terms:

– By engaging in transactions on the Grooft B2B Marketplace, both Party A and Party B assert their understanding and acceptance of these detailed return policies.

– It is imperative for both parties to review and familiarize themselves with these terms regularly, as they are subject to updates and modifications.

This extended Return Policy Agreement aims to establish a transparent and robust framework for conducting B2B transactions, addressing various potential issues that may arise during the course of business on the Grooft B2B Marketplace.

Product Enquiry

Cone Tumble Dryers Global

- No ratings yet

- SKU:ConeTumbleDryers

- 0 sold

- No ratings yet

- SKU:ConeTumbleDryers

Cone Tumble Dryers Global

With a smooth internal finish, complete discharge and elimination of cross batch contamination are realized. Our cone tumble dryers can be designed for up to 500º F jacket temperatures and high vacuum. For superior drying, mixing and ease of cleaning the Orbis Machinery cone tumble dryer is the dryer of choice.

Know your supplier

US

USAvg. response time

1 Hour

On time delivery rate

100%

Order Count

0

Frequently bought together

Rating and Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews

Clear filtersThere are no reviews yet.